The Process

Prep: We grind about 1/32nd of an inch off the entire floor. This opens up the pours of the concrete and adds little bumps to it that we call “profile”. This lets our Epoxy Primer seep down into the concrete before it hardens and the profile also gives it something to stick too. Never accept acid etching as a way to prep concrete, it just doesn’t work.

Crack Repair: We repair all of the cracks in concrete with an epoxy- based crack repair.

Primer: We use an Epoxy Water Vapor Barrier to prime the concrete once it is prepped. This is a two-part epoxy that works well in the presence of water vapor. Concrete can be full of moisture and unfortunately some companies use coatings that are only designed for dry concrete. World class glues are made from Epoxy for good reason. They are sticky! Our coatings from South Fork Concrete Coatings are designed to work in tough conditions, they go down and stay down!

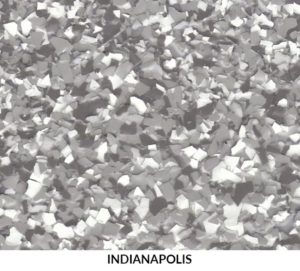

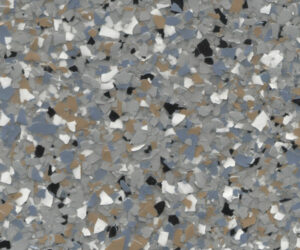

Chips: While our epoxy primer is still wet we broadcast chips of paint into it. These are little chips of paint that are made for this purpose. We broadcast them to refusal. In other words, we put on more chips of paint than the epoxy can hold. We don’t just sprinkle a few on. This gives the floor its color. When the epoxy is dry we diligently scrape it in three directions giving the floor the proper profile for the top coat. This is a very important step.

Top Coat: We use the highest quality Polyaspartics for the top coat to our chip floors. Not all Polyaspartics are created equal and ours have been lab tested to show that they are the best. Although I don’t expect you to know what a Tabor Test, ASTM # 4060 is you can rest assured that we do and this test has shown South Fork Concrete Coatings Polyaspartics to be the toughest on the market. This is a tough, hard, chemical resistant coating.

Our Water Vapor Barrier Epoxies ensure that your coating will not peel up and it will stay down, our paint chips assure that your coating will look beautiful and our Polyaspartic top coat ensures that it will last for a long, long time!

MOST Chip GARAGE FLOORS ARE COMPLETED IN 1 DAY